A bold approach toward sustainable manufacturing

Photo illustration by Joy Smoker; Photo by iStock August 21, 2024

UD contributing research muscle to $26 million NSF Engineering Research Center

The world is waking up to the idea of a circular economy, where products and materials are continually being transformed, reused and recycled instead of being relegated to trash or other pollution. This now even includes carbon dioxide, the greenhouse gas that’s a big driver of extreme weather and climate change.

A new powerhouse collaboration of academic institutions and industries, including researchers from the University of Delaware, is embarking on a bold initiative to transform manufacturing toward zero or negative emissions by converting carbon dioxide ultimately into environmentally friendly chemicals and products with help from some of the tiniest life on the planet — microorganisms.

The Carbon Utilization Redesign for Biomanufacturing-Empowered Decarbonization (CURB) Engineering Research Center, led by Washington University in St. Louis, is funded by a five-year, $26 million grant from the National Science Foundation. The center will support convergent projects in research, education, commercialization, workforce development, and diversity and inclusion, and UD researchers will play a significant role in the effort.

“CURB will create highly efficient chem-bio hybrid systems to convert renewable energy and carbon dioxide into chemicals, fuels and materials,” said Joshua Yuan, CURB director and chair of the Department of Energy, Environmental and Chemical Engineering at WashU. “This will decarbonize U.S. manufacturing and replace a substantial amount of petrochemical products. CURB will drive a new circular carbon economy to fulfill the needs of human society while mitigating carbon emission. That is what is at stake with this center.”

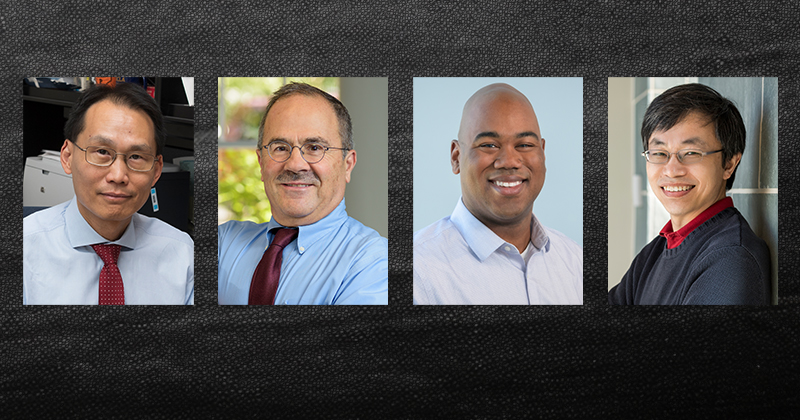

At the University of Delaware College of Engineering, where the graduate program in chemical engineering currently ranks seventh in the nation, Professors Wilfred Chen, E. Terry Papoutsakis, Kevin Solomon and Yushan Yan and their teams will help advance CURB’s research and workforce development goals, with $4.3 million of the grant coming to UD.

“Our UD team has a track record of success in sustainability, and this new center will further expand our efforts toward achieving a carbon-neutral economy,” said Wilfred Chen, Gore Professor of Chemical Engineering and interim associate dean for research and entrepreneurship in the College of Engineering. “We will design new electrocatalysis and biological processes as part of the center’s broader goal to help U.S. manufacturing curb emissions and decrease its ecological footprint by transitioning away from petroleum-based processes and toward biomanufacturing.”

A closer look at CURB research

Through a Hybrid Electro-Bio CO2 Utilization System (HEBCUS), CURB will use electrocatalysis to turn waste carbon dioxide into intermediate substances such as ethanol, acetate and propionate. These intermediates will be compatible with biomanufacturing systems that can more efficiently convert them into a range of products, such as platform chemicals that serve as building blocks for producing other chemicals and materials, biofertilizers containing living microbes that help promote plant health and growth, and other environmentally friendly materials.

The CURB team will design and optimize two types of HEBCUS: one that uses microbial cells to convert carbon dioxide and one that uses enzymes — proteins that speed up chemical reactions. These systems are targeted to be 10 times more efficient than natural processes, such as photosynthesis, and will require fewer steps.

UD experts will contribute to the project on multiple fronts, from optimizing single-celled bacteria that are known for their ability to transform a variety of substances into valuable chemicals, including biodegradable plastics, to integrating renewable energy sources into the biomanufacturing process, and advancing education and workforce development efforts.

The new technology developed by CURB is expected to generate new jobs and create new career development pathways including through workforce upskilling.

UD is one of eight universities involved in the center, which also has more than 30 corporate, innovation and education partners.

NSF has funded 79 Engineering Research Centers across the U.S. since the ERC program began in 1985. This investment has led to more than 240 spinoff companies, more than 900 patents, more than 14,400 total bachelor’s, master’s and doctoral degrees to ERC students, and numerous research outcomes enabling new technologies.

Contact Us

Have a UDaily story idea?

Contact us at ocm@udel.edu

Members of the press

Contact us at mediarelations@udel.edu or visit the Media Relations website