From bean to bar

Photos by Evan Krape August 29, 2024

UD professor and students whip up unique chocolate sweets

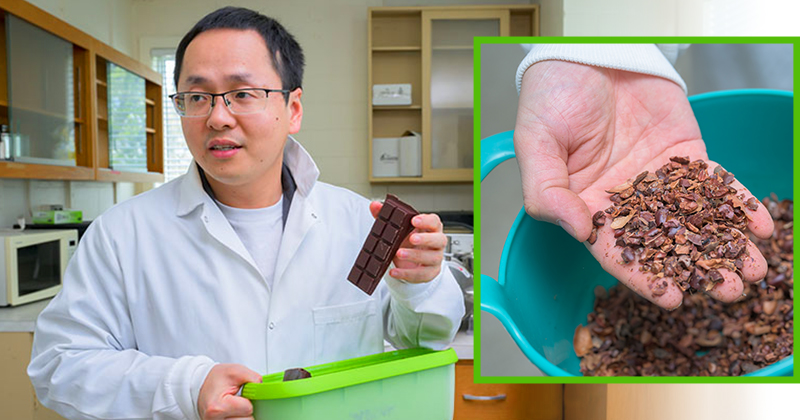

Step into Juzhong Tan’s chocolate factory located in the University of Delaware’s O.A. Newton Building.

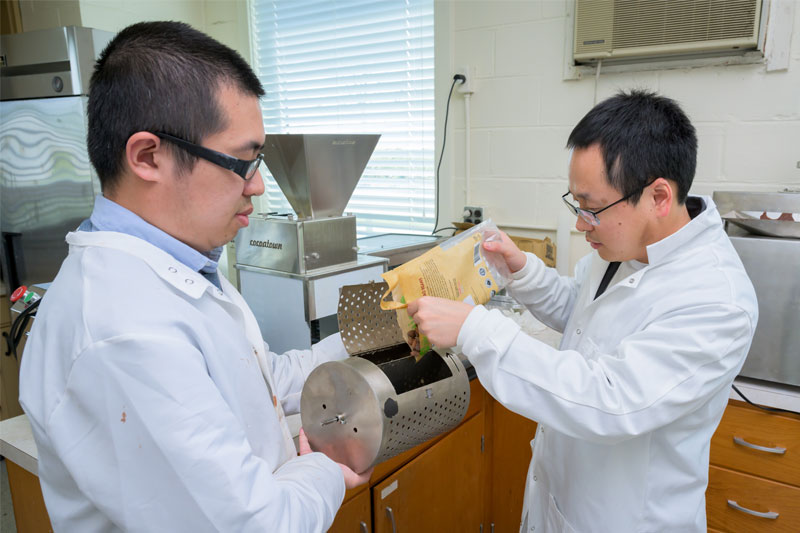

Cacao beans clank against a cracking machine as Tan feeds them through to deshell them. The fresh, pungent smell of chocolate fills the laboratory.

In January, the UD assistant professor of sensory science and food product development set up a “complete chocolate facility” as he calls it, where he turns cacao beans into chocolate bars.

Tan has since worked with his undergraduate and graduate students to make chocolates that run the gamut from whole bean chocolate to matcha green tea chocolate to algae protein chocolate.

“Chocolate is like a wine,” said Tan, a faculty member in the Department of Animal and Food Sciences. “It has to taste different, be diversified.”

Making chocolate

Making chocolate from bean to bar is no small feat.

It requires a dash of Willy Wonka’s “pure imagination” and a sprinkle of patience. Tan’s chocolate that takes only a few seconds to devour actually takes two days to make.

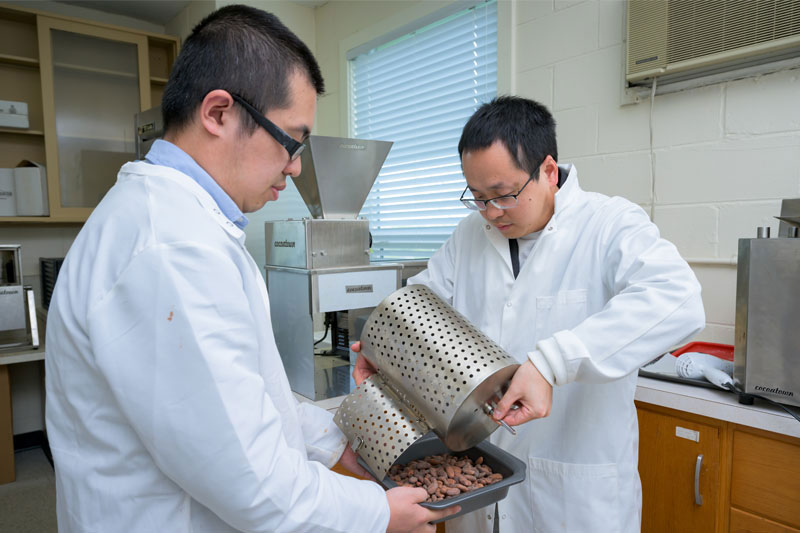

Tan heats up fully fermented, sun-dried cacao beans in a roaster to fully remove moisture and kill bacteria as well as bring out the beans’ flavor. This process will assist the separation of the husks — or outer shells — from the nibs — basically the embryo of the cacao beans. Then the roasted beans will be cracked to obtain a mixture of nibs and husks.

The next step, winnowing, separates the nibs and husks with the help of wind.

The husks get thrown out or can be used to add flavor to tea. The cacao nibs are combined with sugar with additional milk powder (if Tan is making milk chocolates), and the mixture is turned into a fine and smooth chocolate liquor.

Tan said he can also make novel chocolates with new ingredients by mixing, for example, matcha powder or spirulina powder (algae protein powder) with cocoa butter along with sugar to make matcha or spirulina chocolates.

The cacao nibs and sugar mixture spin in a machine, repeatedly crushed and sheared by roller stones, for about 48 hours before they turn into a smooth liquid — called the conching process. Then, Tan moves the liquid to a tempering machine. This heats up and cools down the mixture to obtain desirable stable forms of fat crystals. This gives chocolate a shiny appearance, snappy texture, and stable shelf life.

“We play with the temperature,” Tan said, “in order to achieve a specific texture and appearance.”

In the spring 2024 semester, Tan and his students made about 100 pounds of chocolate. That chocolate became popular among CANR students, faculty, and staff. Much was taken home by department faculty and staff to share with their families.

Seizing opportunity

Chocolate is a big market. According to the U.S. Department of Agriculture, the U.S. exported chocolate and cocoa products valued at $1.9 billion in 2023. But Tan said there aren’t a lot of people being trained to make those products.

“I want to improve the education, the teaching programs, and make them unique,” Tan said.

Tan hopes the training his complete chocolate facility provides will give food science students a leg up in internships and jobs.

“Students gain the capability to support local chocolate manufacturers,” Tan said. “They do a lot of manufacturing, sensory, product development. They would be a good source for a chocolate company.”

Additionally, all of the equipment in Tan’s facility comes from small business chocolate equipment manufacturer CocoaTown LLC out of Atlanta. Tan hopes to collaborate with other small chocolate-related companies, envisioning small companies could assist with evaluating students’ products and supporting students with internships.

UD undergraduate and graduate students who enrolled in Tan’s Food Science Capstone (ANFS 411/611) got a taste of the chocolate-making industry. The class allowed them to learn about the processing of food, how to use raw materials (like cacao beans) to make finished products, and how to package those products. And, of course, there were more than enough samples of chocolate to go around.

“It was really cool to be able to eat something that my whole class had made ourselves,” said Gabriella Strocko, a UD Class of 2024 food science major.

Strocko learned that making chocolate takes time. It’s a science and an art. She enjoyed Tan’s class immensely.

“I would love to work in the chocolate industry eventually,” Strocko said.

For now, Strocko is focused on starting her Ph.D. in Animal and Food Sciences this fall at the University of Delaware. She’s going into it with food safety knowledge thanks to Tan’s class. Things like keeping the chocolate machines cleaned and how to safely handle the food to prevent foodborne illness.

Equipped with a Ph.D. degree in Chemistry, Ruogu Tang, a postdoctoral researcher who has joined Tan's lab recently, says the most fascinating part about the chocolate-making process is the opportunity to apply his chemistry knowledge.

“The knowledge and skills I obtained during making chocolate have become another piece of the puzzle in my research career,” Tang said. “I am pretty confident that we could make significant achievements in developing safe, nutritious, and appealing food products that contribute to public health and well-being.”

For Vaidehi Dendukuri, Tan’s knowledge about chocolate-making helped her learn how to perfect her own process. The food science graduate student student has made dark chocolate at home before. But it’s been challenging.

Sometimes, Dendukuri said, her chocolate comes out with a white, tiny film-like texture on the top.

“I always get blooms on top of my chocolate. It doesn’t melt well and it’s a brittle texture,” said Dendukuri, who is concentrating on business and entrepreneurial leadership.

Tan’s class helped Dendukuri realize the importance of the conching process in creating a chocolate with a smooth final texture. Now that she understands that process, she’s on the way to achieving her goal of becoming a jack-of-all-trades food technologist.

“I want to open each and every path for myself where I could work on any products existing on the market or that don’t exist on the market yet” Dendukuri said. “I want to be the multi-talented one.”

And chocolate, Dendukuri said, is the perfect product to start with.

“As food technologists, we could experiment with chocolate with different kinds of sweeteners, alternatives to sweeteners apart from sugars,” Dendukuri said. “We could add matcha, prebiotics, probiotics to improve its nutritional quality and make them as functional chocolates.”

Tan has high hopes to partner with local chocolate producers in the area to sell chocolate products he and his students make at UD.

In the fall semester, Tan will teach a food sensory class (ANFS 367). Students will have the opportunity to create novel chocolate and conduct sensory evaluations where people will rate the chocolates based on multiple attributes such as taste and texture.

Some day, Tan said, UD-made chocolate could even make its way to shelves at UDairy Creamery. He says hopefully, he and his students can collaborate closely with UDairy for student training, class demos, and collaborative research. It could make life just a little bit sweeter.

“We’re incubating for the future,” Tan said.

Contact Us

Have a UDaily story idea?

Contact us at ocm@udel.edu

Members of the press

Contact us at mediarelations@udel.edu or visit the Media Relations website